突出优势

(1) 自动化程度高,操作简便,人员投入少。

(2) 产品质量好,粒度均匀,含粉尘少。

(3) 高产低耗,设备性能优,生产速度快,耗能少。

(4) 适用范围广,可加工不同硬度和湿度的物料。

(5) 矿山破碎线因其高效、节能、环保等特点,在矿山、建筑、公路等领域得到广泛应用。

工艺流程

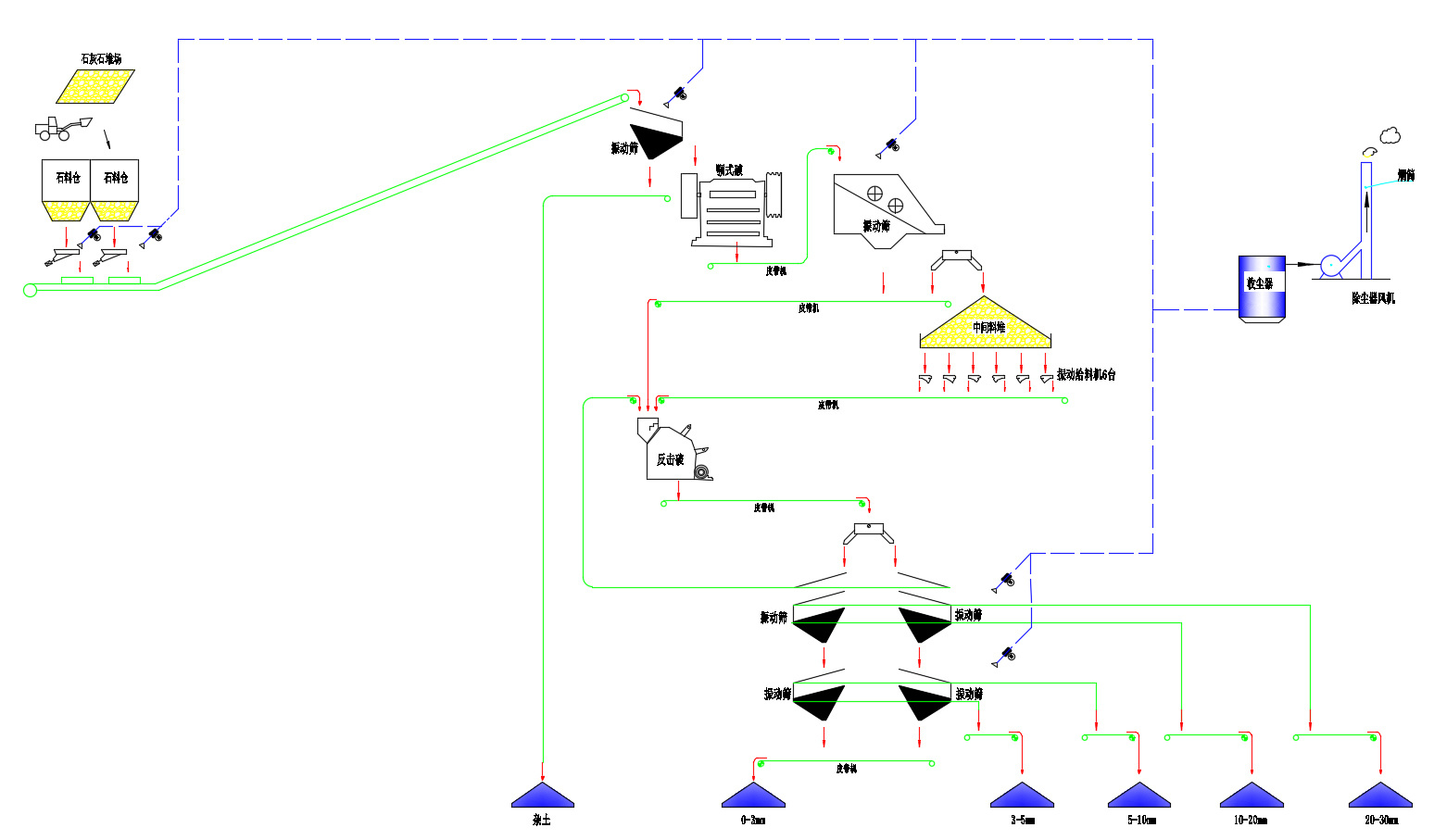

破碎生产线采取了多段破碎的方式,可以将原本粒径比较大的石灰石原材料,破碎成细度比较细的成品料。大块石料先经过两台重型锤式反击破碎机进行粗碎,粗碎后的物料经过筛分后得到一部分成品料,筛分出来的大块物料返回整形锤式破碎机进行细碎整形,经过再次破碎的物料经过振动筛再次筛分出不同粒度的成品料。并且每个环节、每个除尘口都配置矿用除尘器,源头收尘,保障绿色生产。破碎物料,产品级配合理,生产的成品料合格率在90%以上,保证了产品的质量,多级输送筛将破碎的成品料输送到对应的加工料仓内,时能力可以达到设计产量。

(1)喂料:原料由喂料机(如振动给料机)将大块物料持续、均匀送到初碎设备。

(2)粗碎:主要依赖颚式破碎机,其强大的破碎力适用于各种硬度的矿石,作为粗碎的首选。

(3)中细碎:根据矿石硬度灵活选择破碎机。软质矿石优选反击式破碎机;中硬及以上的矿石则选择圆锥破碎机。

(4)筛分:经过破碎处理的砂石料,需通过筛分作业来分级。振动筛集筛分与给料功能于一体,能有效控制成品砂石料的规格。

(5)输送:皮带输送机主要用于运送物料以及连接各个设备,使各个设备有序运行。不满足粒度要求的石子会返料进破碎机再次破碎。

此工艺流程设计需根据生产线的工作现场、物料特点、产量需求等合理配置设备,以节省能耗和减少时间。

工艺流程图

技术参数

产能(t/h) |

50⁓3000 |

主要设备 |

振动给料机、重型锤式破碎机、整形破碎机、振动筛、双转子制砂机、轮式洗砂机、胶带输送机、斗式提升机 |

成品粒度/mm |

石料26-31.5、15-26、10-15、5-10、0-5、机制砂3.5-6、0-3.5(可定制) |

适用矿石 |

石灰岩、花岗岩、玄武石 |

免费获取更多解决方案

如果您对我们的产品感兴趣,请留下您的电子邮件,我们将尽快与您联系,谢谢!