突出优势

(1)系统产生的噪音小,振动筛寿命长,筛板便于更换。

(2)可用于干法筛分和湿法筛分,筛下物限上率大幅降低,可将小块筛选出来,从而产生效益。

(3)可进行单层、双层或三层等多种筛面组合形式。

(4)筛板具有单位面积处理量大,筛分效率高等有点,广泛应用于中细粒度、高粘度、潮湿等难筛物料的筛分作业。

(5)系统粉尘污染低、扬尘少,作业岗位洁净环保,符合环保要求。

工艺流程

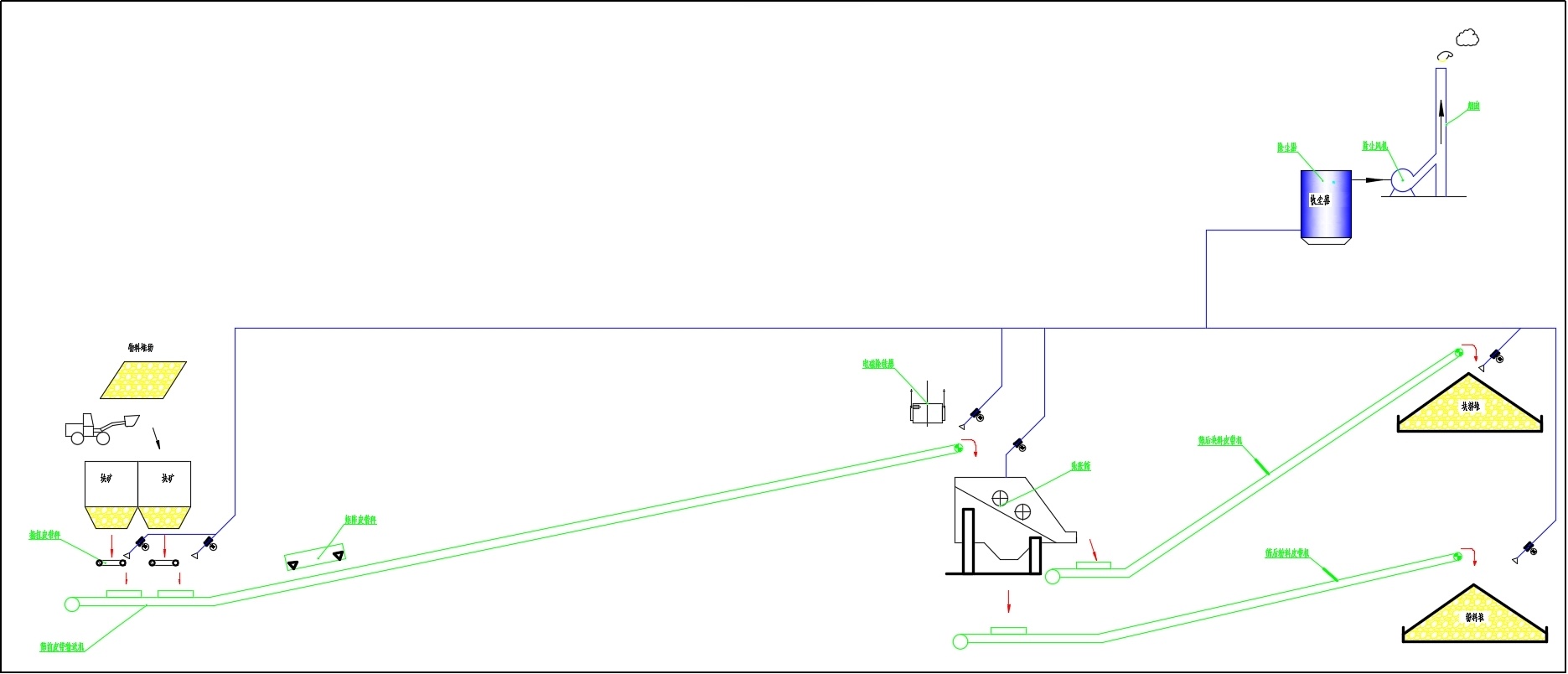

物料输送:主要由受料仓、拖拉皮带秤、皮带输送机或斗式提升机、称量装置、电磁除铁器等组成。待筛分物料由装载机送至受料仓,经拖拉皮带秤、皮带输送机或斗式提升机将定量的物料输送至振动筛进料口。

物料筛分:主体为各类振动筛本体,例如直线筛、香蕉筛、弛张筛、滚筒筛等等。物料在此单元经过各级筛板分离后落至筛后皮带输送机,再被输送到相应粒度的存储区或储仓。

生产线投运时先将物料推送至受料仓,保证仓内不空料。系统可实现一键启动控制,依次开启筛后皮带输送机、振动筛、筛前皮带输送机(斗式提升机)、拖拉皮带秤,物料进入筛分处理系统。停止生产线运行时,设备停止顺序与开启时相反,每个设备启停间隔时间可根据物料特性及现场调试情况进行设置,小时处理量可在控制画面进行给定。各设备均设有故障报警功能,可及时提醒主控人员了解设备运行情况。

生产线设有环境除尘一套,除尘点主要设置在落料点处,例如拖拉皮带秤下料处、皮带机机头下料处,振动筛设有独立收尘口,除尘风量可保持各扬尘点处于负压状态,避免扬尘外泄,除尘器过滤后排放指标满足环保要求。

技术参数

| 产能(t/h) | 50 ⁓ 5000 |

| 主要设备 | 主要配套设备型号及技术经济指标 |

| 筛机宽度/mm | 1000 ⁓ 5200 |

| 筛机长度/m | 4 ⁓ 12 |

| 倾角/度 | 5 ⁓ 30 |

| 粒度处理范围/mm | 3 ⁓ 80 |

| 筛下物合格率/% | >92 |

| 筛分效率/% | 80 ⁓ 90 |

| 筛网寿命/h | 4000 ⁓ 6000 |

| 激振器使用寿命/年 | >10 |

| 处理物料 | 块矿、原煤、钾盐、粮食、砂石骨料 |

免费获取更多解决方案

如果您对我们的产品感兴趣,请留下您的电子邮件,我们将尽快与您联系,谢谢!