突出优势

(1)较高的选粉率,提高经济效益。

(2)系统产能大,系统安全性高。

(3)系统设计紧凑、物料输送流畅。

(4)粉尘污染低、扬尘少,作业岗位洁净环保,符合环保要求。

(5)工程造价合理,投入产出比较高。

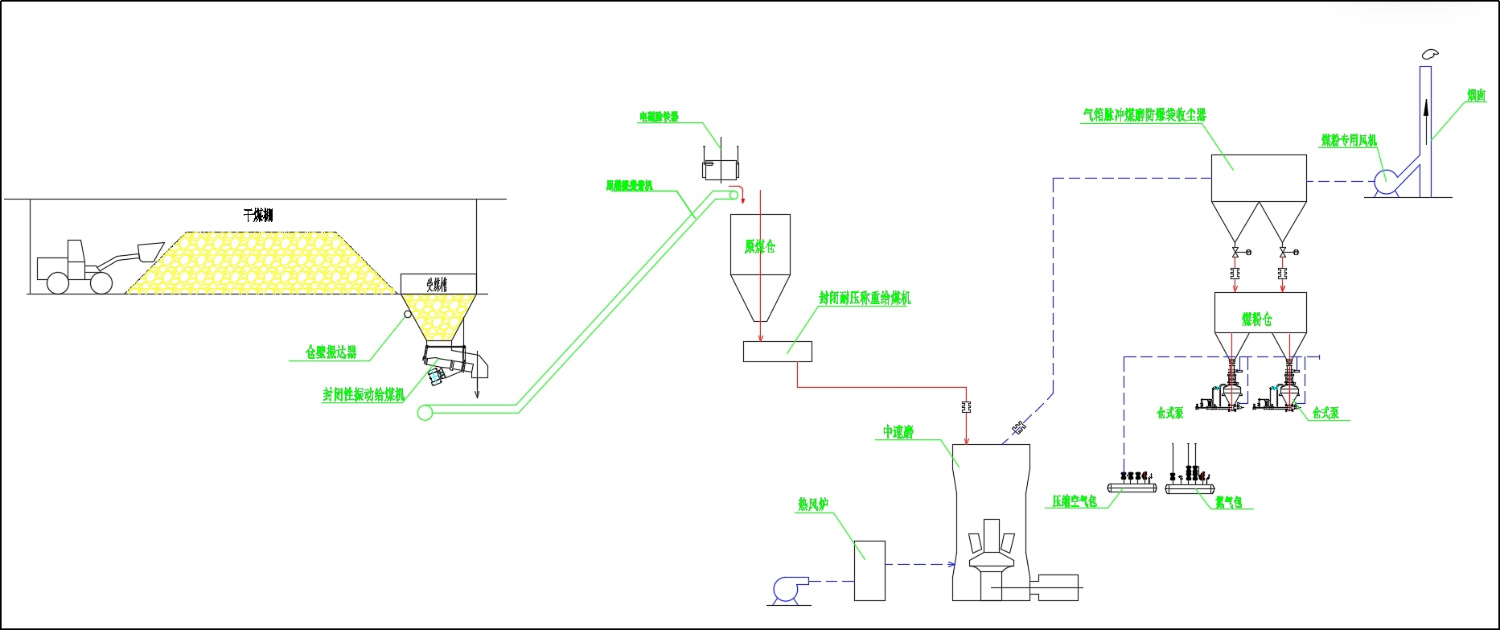

工艺流程

(1)原煤储备及供煤系统

原煤储备系统设计为干煤棚,供煤设施设计由一套给煤设施和一套上煤系统组成。其任务是接受汽车运来的合格洗精煤,并将其输送到煤粉制备间主厂房内的原煤仓。合格粒度的原煤由汽车运入干煤棚,用装载机及其它的辅助机械进行倒堆、造堆、供煤。供煤时用装载机将煤运入受煤槽内,由给煤机、大倾角带式输送机(斗式提升机)送入制粉间的原煤仓内。

(2)磨粉系统

磨粉系统包括:原煤仓、给煤机、磨煤机、布袋收粉器、煤粉仓、煤粉风机和有关工艺管道。

原煤由供煤系统送入原煤仓,进入磨粉系统,再经各闸门、给煤机给入磨煤机。在磨机中同时进行煤的干燥和磨细,经过研磨,煤粉与200℃~350℃的热风进行传质传热,水分自煤粉进入烟气,煤粉被热风烘干,而后,煤粉随气流进入选粉机分选,选出的粗粉再次回到磨内研磨,细粉则继续随气流由煤粉风机,吸入布袋收尘器,经布袋收尘器分离,落入煤粉仓中。

经布袋收尘器过滤后达到国家排放标准的气体排放大气,整个制粉系统为负压操作。在磨煤机研磨过程中,煤中较大的硬物,如石子、煤干石等经旋转刮板排至渣箱中,以便定期清理。

(3)烟气炉系统

干燥所用介质主要是烟气炉产生的烟气和空气的混合气体,干燥气温度一般为200⁓350℃。一套烟气炉系统中需设一台烟气炉,烟气炉设一组烧嘴,烧嘴燃烧能力2500 Nm3 /h,使用燃料及热值:自制煤粉,烟气炉点火方式为自动点火。在烟气炉与磨机之间设有烟气管道和切断阀、调节阀等设备。

烟气炉系统紧靠制粉、输粉车间布置在厂房外,露天布置,烟气炉本体坐在高架平台上,其它管道和阀门架空布置。在阀门处设有检修平台。烟气配备系统控制统一布置在制粉、输粉车间操作室内。

工艺流程图

技术参数

| 产能(t/h) | 5⁓6 | 7⁓8 | 10⁓12 | 15⁓18 | 20⁓24 |

| 主要设备 | 主要配套设备型号及技术经济指标 | ||||

| 磨机直径/mm | 1100 | 1200 | 1300 | 1500 | 1700 |

| 磨机功率/kw | 132+11 | 180+18 | 200+22 | 280+30 | 315+37 |

| 煤粉选粉器 | FGM64-7(M) | FGM96-2×4(M) | FGM96-2×5(M) | FGM96-2×7(M) | FGM96-2×10(M) |

| 热风炉风量/Nm3 | 15000⁓18000 | 22000⁓25000 | 31000⁓34000 | 46000⁓55000 | 62000⁓75000 |

| 煤粉细度⁓200目/% | ≥90 | ||||

| 煤粉水分/% | ≤2 | ||||

| 热风进口温度/℃ | 220 ⁓ 350 | ||||

| 磨机出口温度/℃ | 60 ⁓ 70 | ||||

| 烟气排放浓度(mg/Nm3) | ≤30 | ||||

| 年工作日天数/天 | ≥330 | ||||

| 操作人数/(人/班) | 2⁓3 | ||||

免费获取更多解决方案

如果您对我们的产品感兴趣,请留下您的电子邮件,我们将尽快与您联系,谢谢!