Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

Exploring the Charm and Applications of Countercurrent Calcination Lime Kilns

Mar 29,2025

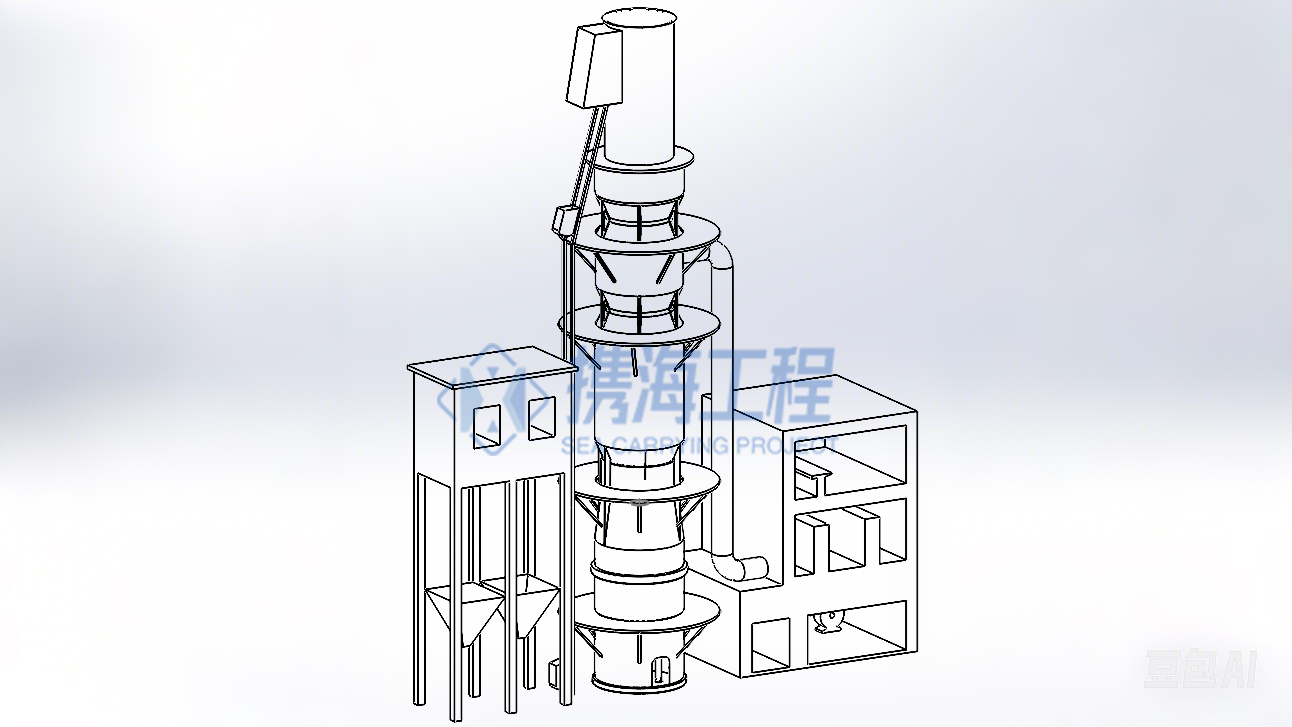

Definition and Importance of a Cross-Flow Rotary Lime Kiln

In modern industry, the cross-flow rotary lime kiln is an important technological tool. Through its unique design and efficient operation, it can heat limestone to high temperatures to produce high-quality quicklime. This process not only improves the quality of lime but also significantly increases production efficiency. Speaking of which, it is necessary to delve deeper into this amazing piece of equipment.

Working Principle of a Cross-Flow Rotary Lime Kiln

The working principle of a cross-flow rotary lime kiln is relatively simple yet efficient. First, limestone enters the kiln through the feed port. Then, hot air flows horizontally from the bottom of the kiln, forming a continuous heat flow. The hot air comes into full contact with the limestone, causing it to heat up rapidly, eventually reaching the temperature required for calcination. The whole process is like a precise machine, with all parts working together to ensure high-quality lime output.

Technical Advantages of a Cross-Flow Rotary Lime Kiln

Cross-flow rotary lime kilns have several technical advantages. First, they are energy-efficient and environmentally friendly. Due to their efficient heat exchange system, they can significantly reduce energy consumption, which is particularly important in the current context of promoting green development. In addition, the kiln has a high degree of automation and is easy to operate, greatly reducing labor costs. Furthermore, the kiln's temperature control system ensures uniform calcination of the lime, effectively improving product quality.

Wide Applications

Cross-flow rotary lime kilns are widely used in many industries. For example, in the construction industry, quicklime is an important building material used in the production of concrete and cement. In the steel industry, lime is a flux in the smelting process, removing impurities from iron ore. In addition, the environmental protection industry has begun to use quicklime for wastewater treatment and soil improvement, demonstrating its diverse application potential.

Future Development Trends

With the continuous advancement of technology, cross-flow rotary lime kilns are constantly being upgraded. In the future, intelligence will become an important direction of development. By introducing the Internet of Things and big data technology, the production process will be more refined, with real-time monitoring of energy consumption and product quality to improve overall efficiency. At the same time, increasing environmental protection requirements will also drive kiln technology towards low-emission and low-energy consumption.

Summary

In general, as important equipment in modern industry, cross-flow rotary lime kilns not only improve the production efficiency and quality of lime but also provide strong support for the development of various industries. With the continuous advancement of technology, we have reason to believe that the future of cross-flow rotary lime kilns will be brighter, and they will surely play a greater role in more fields, creating greater value!

Previous article

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province