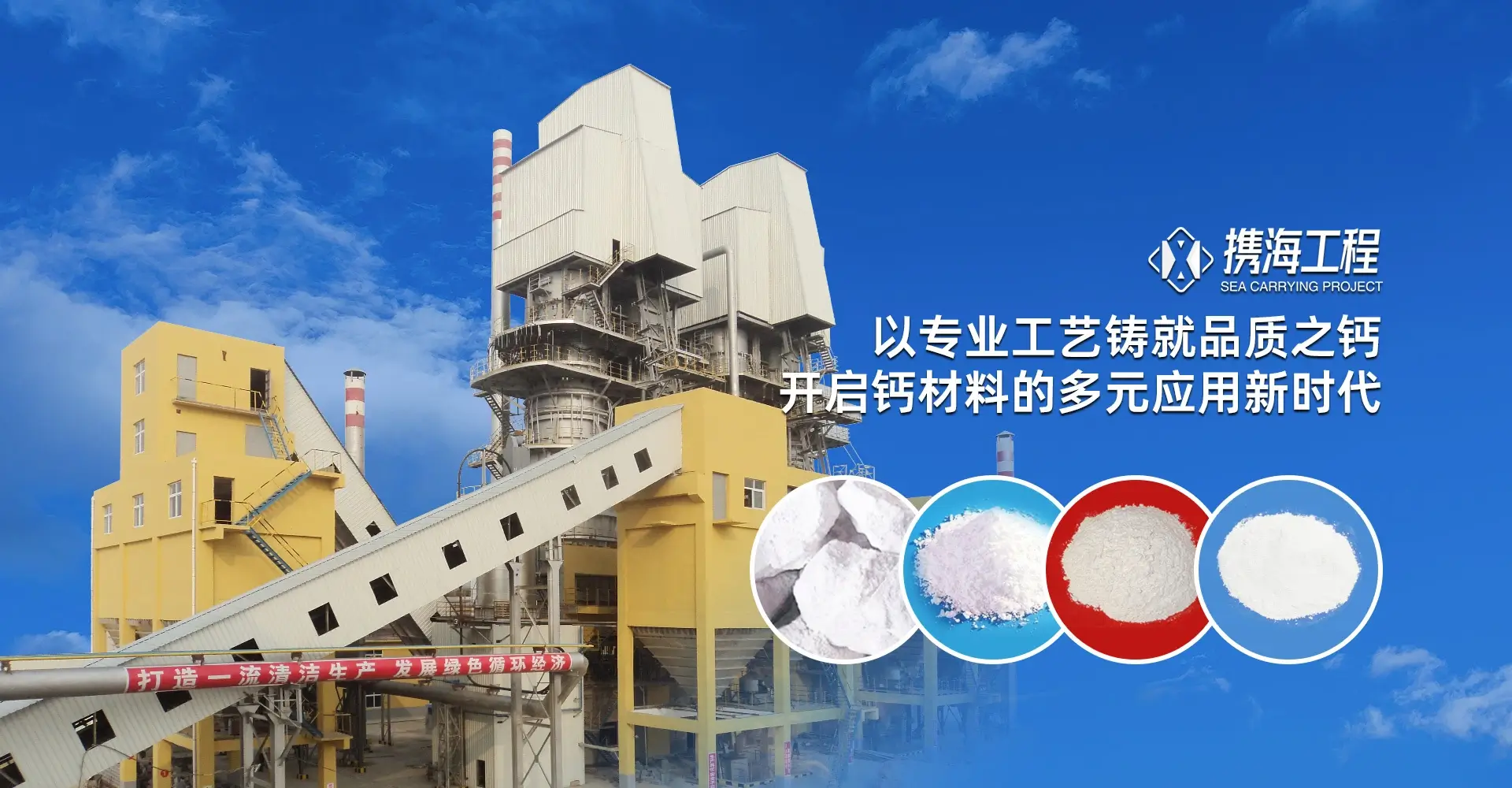

Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

Common Problems and Solutions in Lime Production Lines

Mar 26,2025

Introduction

In modern industry, the lime production line is an indispensable production line. It not only plays an important role in the construction and metallurgical industries, but also has a positive impact on environmental protection. However, many people have some doubts about the lime production line, so today we will discuss these common questions.

What is the basic process of the lime production line?

The basic process of the lime production line can be divided into several main steps: First, limestone is mined from limestone mines; then, the limestone is crushed to a certain particle size by a crusher; then, it is sent to a high-temperature furnace for calcination, and the limestone decomposes into calcium oxide and carbon dioxide at high temperatures; finally, after cooling and grinding, finished lime is produced. In short, it is a complete cycle from raw materials to finished products. Doesn't it sound simple?

What are the key equipment of the lime production line?

Several key pieces of equipment are indispensable on this production line. First, the crusher is the equipment that crushes large pieces of limestone into small pieces, and its efficiency directly affects subsequent processing; second, the high-temperature furnace is the core equipment for calcination, and proper temperature control can ensure the quality of lime; finally, the cooler and pulverizer are the key to subsequent processing, ensuring the particle size and quality of the finished product.

How to improve the efficiency of the lime production line?

There are several measures to improve the efficiency of the lime production line. First, regularly maintain the equipment to ensure that all equipment is in optimal condition; second, reasonably arrange the production plan to avoid equipment idling and idleness; finally, adopt an advanced automated control system to achieve intelligent management of production. In this way, efficiency will naturally increase!

How to solve the environmental problems of the lime production line?

Today, with increasing emphasis on environmental protection, environmental problems of the lime production line have also become a focus. By adopting advanced dust removal and exhaust gas treatment equipment, it is possible to effectively reduce the dust and toxic gases produced during production. In addition, using carbon dioxide capture technology to recycle and utilize the carbon dioxide produced during production not only reduces emissions but also achieves resource recycling, which is a win-win situation!

How to choose suitable equipment for the lime production line?

The selection of suitable equipment for the lime production line mainly considers several aspects: First, the production capacity, selecting suitable equipment according to one's own needs; second, the energy consumption of the equipment, energy-saving equipment can reduce production costs; finally, After-sale Service, good After-sale Service can ensure the smooth operation of the equipment during use. If these factors can be considered, it will not be so difficult to choose suitable equipment.

Conclusion

Through the above analysis of common problems of the lime production line, we hope to help everyone better understand the operating principles and precautions of this production line. Whether you are a novice or an expert, understanding these issues will allow you to be at ease in actual operation!

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province