什么是双膛窑石灰窑

2024-12-16

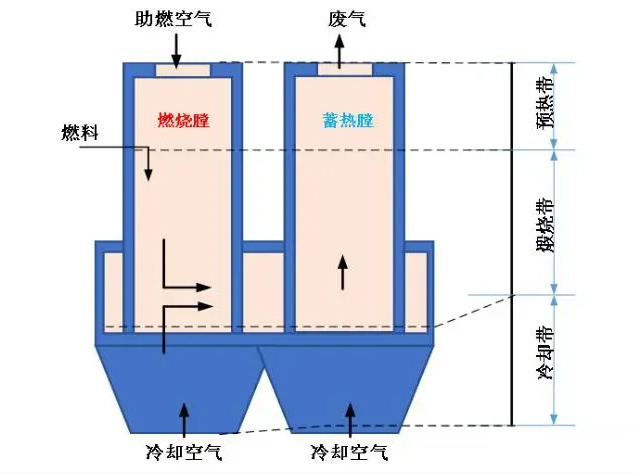

双膛窑石灰窑是一种常见的石灰生产设备,也称为双膛窑石灰窑炉。它是一种节能环保的石灰窑炉,主要由两个窑膛组成,采用通道相连,两个窑膛之间可以通过通道进行热量的互换。一个窑膛煅烧,另外一个窑膛储热,每隔10-15分钟进行一次互换,煅烧石灰的质量好,活性度高。

双膛窑的结构

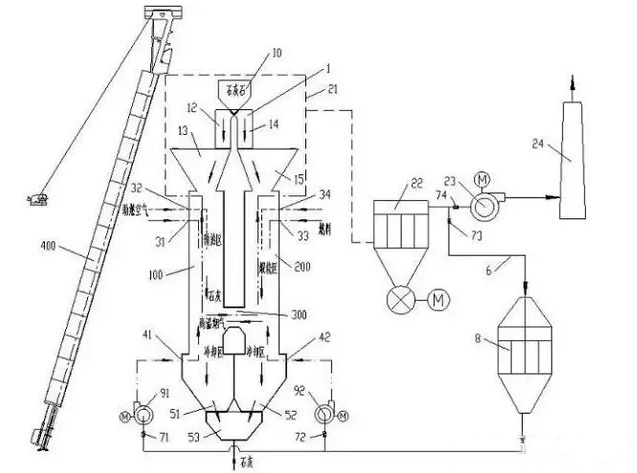

双膛窑由两个相邻的圆形窑膛组成,每个窑膛都有一个独立的燃烧室。在生产过程中,石灰石和燃烧材料通过上部进入窑膛,然后在高温下反应,产生石灰和石灰石灰。石灰和石灰石灰从下部排出,石灰石和燃烧材料则从上部进入。这种结构使得窑膛的生产过程可以连续进行,并且可以提高生产效率。

双膛窑煅烧工艺流程

双膛窑采用了建立两个窑膛用来煅烧石灰,其中A膛和B膛在煅烧带底部相互连通,物料沿两个窑膛向下运行。

在窑膛A煅烧时,燃烧空气和燃料在窑膛A中与物料并流,使*热的火焰与温度较低且吸收热量大的物料接触,相对而言,温度较低的燃烧气体与逐步煅烧好的物料接触,以达到均匀煅烧条件,且取得很高热效率,燃烧后的产物与物料分解出的CO2经连接通道进入B膛。此时B膛作为蓄热窑膛,窑膛中的石灰石从废气中吸取热量,同时使废气冷却到较低温度,物料蓄积热量,在下*周期时用于加热参加燃烧之前的助燃空气。在这种情形下窑膛A为燃烧窑膛,体现了并流特点;窑膛B体现了蓄热窑膛,体现了蓄热特点。下*周期将相互轮换,即窑膛A成为蓄热窑膛,窑膛B成为燃烧窑膛。如此循环往复,石灰石得以连续煅烧。

燃料类型

1. 煤炭:煤炭是一种常见的燃料类型,也可以用于双膛石灰窑的燃烧。不同种类的煤炭具有不同的热值和燃烧性能,可以根据需要选择不同种类的煤炭。

2. 天然气:天然气是一种干净、便捷的燃料类型,也可以用于双膛石灰窑的燃烧。天然气的热值较高,燃烧产生的废气较少,对环境污染较小。

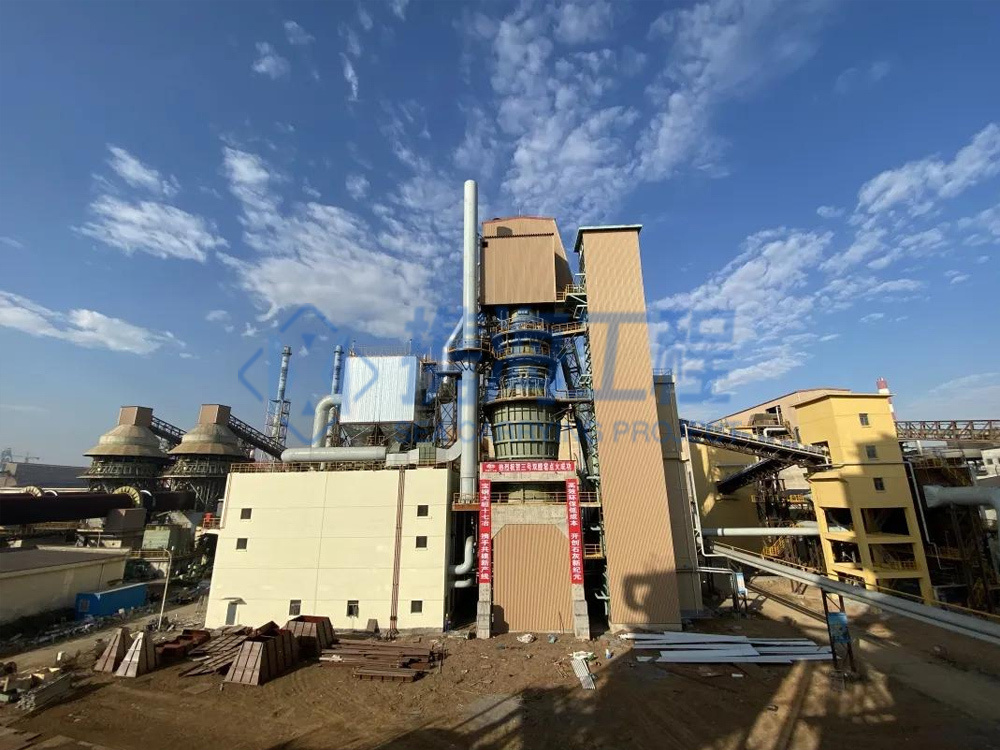

生产规模及产品大纲

1生产规模

新建1座600TPD双膛窑生产线。生石灰生产能力为块灰(≥10mm)18万吨/年,粉灰(≤3mm)2万吨/年。

2产品质量

煅烧后的石灰产品质量符合YB/T042-2004的要求,主要指标:活性石灰理化指标表见表2-1:

表2-1

说明:活性度是指取活性石灰50g,用4N HC1滴定,10min滴定值。

石灰石质量符合YB/T5279-2005中PS520标准。

3能耗指标

单位产品的热耗,≤850Kcal/Kg石灰。

4废气排放浓度

石灰窑大气污染物排放应达到《工业炉窑大气污染物排放标准》(DB13/1640-2012)。

双膛窑优势

双膛石灰窑是一种传统的石灰窑,其优势主要包括以下几个方面:

1. 窑体结构简单:双膛石灰窑的结构相对简单,容易制造和维护,不需要复杂的技术和设备,适合于一些经济条件较差的地区使用。

2. 煅烧效果稳定:双膛石灰窑的煅烧效果相对稳定,不容易出现煅烧不均匀、石灰质量差等问题,可以保证石灰的质量。

3. 燃料使用范围广:双膛石灰窑可以使用多种类型的燃料,如木柴、秸秆、煤炭等,可以根据当地的资源情况和经济条件选择合适的燃料。

4. 环保节能:相比于一些现代化的石灰窑,双膛石灰窑的烟气排放量较少,对环境污染相对较小。同时,由于其结构简单,热能利用率较高,相对节能。

5. 灵活性强:双膛石灰窑的操作较为简单,可以根据生产需要进行灵活调整和改变,适应不同的生产要求。 总的来说,双膛石灰窑具有操作简单、煅烧效果稳定、燃料使用范围广、环保节能等优势,适用于一些技术水平有限、经济条件较差的地区。

下一篇