Double-beam lime vertical kiln gas-coal dual-use lining ceramic combustion beam core

Apr 27,2025

I. Introduction

In the field of lime production, dual-beam lime kilns using a mixture of gas and coal are widely used due to their durability and energy-saving advantages. The ceramic combustion beam core, as a key component, plays a crucial role in the kiln's combustion efficiency, stability, and service life. This article will delve into the characteristics, advantages, and application highlights of the ceramic combustion beam core in dual-beam lime kilns using a mixture of gas and coal.

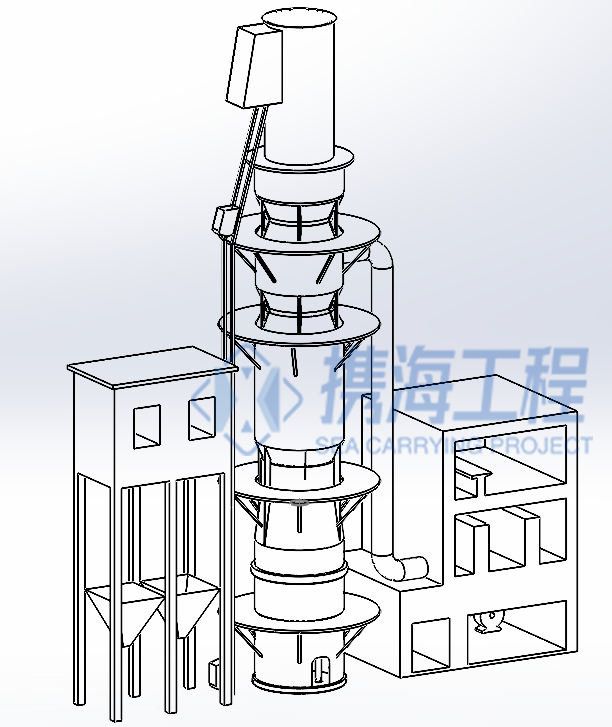

II. Brief Description of the Working Principle of Dual-Beam Lime Kilns

Dual-beam lime kilns introduce fuel and combustion air into the calcination zone via upper and lower combustion beams. In the gas-coal mixed combustion mode, coal gas and coal powder are mixed in a certain proportion, and then sprayed into the kiln through the burner of the combustion beam, where it vigorously mixes with the preheated combustion air, releasing a large amount of heat for calcining limestone. This structure makes the temperature distribution in the kiln more uniform, improving the quality and efficiency of lime calcination. For example, in some lime kilns that are part of steel plants, the use of a dual-beam structure has effectively improved the stability and quality of lime supply, meeting the needs of steelmaking for high-quality lime. 。

III. Structural Analysis of the Ceramic-Lined Combustion Beam Core

(1) Ceramic Lining Layer

The inside of the combustion beam core uses special ceramic materials as the lining. Common materials include silicon carbide ( SiC ), silicon nitride ( Si₃N₄ ) ceramics, etc. Taking silicon carbide ceramics as an example, they have excellent high-temperature performance and can withstand 1600℃ or higher temperatures, far exceeding the typical calcination temperature in a lime kiln ( 1000 - 1200℃ ). At the same time, silicon carbide ceramics have high hardness and can effectively resist wear caused by the high-speed scouring of fuel and combustion air. Compared to traditional metal linings, their wear resistance is several times higher, significantly extending the service life of the combustion beam core. In some long-running lime kilns, the operating time of combustion beam cores with ceramic linings is extended by 2 - 3 years, reducing production losses and maintenance costs caused by frequent replacements.

(2) Metal Support Structure

The exterior is made of a high-strength metal material to form a support frame, such as high-temperature alloy steel. This structure, on the one hand, provides stable support for the ceramic lining, ensuring that the ceramic lining does not shift or damage under complex operating conditions such as high temperature, high pressure, and mechanical vibration; on the other hand, the metal frame has good thermal conductivity, which can evenly transfer part of the heat generated by combustion to prevent local overheating. For example, the use of steel containing chromium ( Cr ), nickel ( Ni ) and other alloying elements can enhance the oxidation and deformation resistance of the metal frame in high-temperature environments, ensuring the overall structural stability of the combustion beam core.

(3) Fuel and Air Channel Design

The inside of the combustion beam core is designed with multiple independent fuel and air channels. The fuel channels are responsible for accurately precisely transporting the mixed fuel to each burner. The channel walls are smooth to reduce fuel transport resistance and ensure the stability and uniformity of fuel supply. The air channels introduce preheated combustion air into the kiln, where it fully mixes with the fuel at the burner outlet. Reasonable channel layout and cross-sectional design can optimize the air-fuel mixing ratio and mixing effect, promoting combustion. For example, by numerical simulation and actual debugging, the appropriate number of channels, pipe diameter, and angle are determined, so that the fuel and air achieve a fully mixed state before entering the kiln, improving combustion efficiency and reducing fuel consumption. 。

IV. Advantages of Ceramic-Lined Combustion Beam Cores

(1) Excellent High-Temperature and Corrosion Resistance

The inside of a lime kiln contains high temperatures and corrosive gases produced by the decomposition of limestone, such as carbon dioxide ( CO₂ ), and a small amount of sulfur dioxide ( SO₂ ). Ceramic materials have a strong resistance to these corrosive media. For example, silicon nitride ceramics, even CO₂ and SO₂ in a mixed gas environment, show almost no visible corrosion marks after long-term operation. This characteristic ensures the stable operation of the combustion beam core in the harsh kiln environment, reducing the risk of equipment damage caused by corrosion, extending the overall service life of the equipment, and reducing maintenance costs.

(2) Improved Combustion Efficiency and Lime Quality

Due to the good thermal insulation performance of the ceramic lining, heat loss during the combustion process is reduced, and the heat generated by combustion is more concentratedly used to calcine limestone. At the same time, the optimized fuel and air channel design promotes the full mixing and combustion of gas and coal, making the kiln temperature more uniform and stable. In actual production, lime kilns using ceramic-lined combustion beam cores have significantly reduced under- and over-burned lime rates and significantly improved activity. For example, after a certain lime producer replaced the ceramic-lined combustion beam core, the under-burned lime rate decreased from the original 8% to 3% or less, and the activity increased from 350ml to 400ml The above-mentioned lime production process achieves high-quality standards, meeting the demands of more high-end clients.

(III) Significant Energy Saving and Consumption Reduction

Good thermal insulation performance and fully combustion efficiency significantly improves fuel utilization. On the one hand, it reduces extra fuel consumption due to heat loss; on the other hand, the stable and suitable calcination temperature shortens the calcination time of limestone, further reducing energy consumption. According to statistics, compared with lime kilns that do not use ceramic combustion beam cores, lime kilns using this technology can reduce unit product energy consumption by 10% - 15% . This not only saves a large amount of fuel costs for enterprises but also conforms to the current requirements of energy conservation and emission reduction, improving the sustainable development capabilities of enterprises.

V. Application Points and Maintenance Suggestions

(I) Installation and Debugging Points

When installing the ceramic combustion beam core liner, ensure that its connection with the combustion beam is tight and well-sealed. Install it strictly according to the design requirements to ensure the accurate connection of the fuel and air passages. During debugging, finely adjust the flow rate and ratio of fuel and air, monitor parameters such as kiln temperature distribution and combustion flame status, and determine the best combustion conditions. For example, use high-temperature thermocouples to monitor the temperature at different positions in the kiln in real-time and adjust the fuel and air valve openings according to the temperature feedback to ensure uniform and stable combustion. 。

(II) Daily Maintenance Precautions

Regularly check the ceramic lining of the combustion beam core for damage or detachment. If problems are found, repair or replace them promptly. Inspect the metal support structure for deformation, corrosion, etc. and perform anti-corrosion treatment if necessary. At the same time, clean the scale and impurities in the fuel and air passages to ensure smooth passages. It is recommended to perform a major maintenance check every certain production cycle (e.g., 3 - 6 months) 大 major 。

(III) Fault Diagnosis and Handling

When unstable combustion or abnormal temperatures occur in the kiln, it may be related to the combustion beam core. This can be checked by detecting the fuel supply pressure, air flow, burner combustion status, etc. If the ceramic lining is found to be damaged, causing heat leakage or uneven fuel/air mixing, the damaged parts should be replaced promptly; if the deformation of the metal support structure affects the normal operation of the combustion beam core, the deformed parts should be repaired or the corresponding components replaced. 。

VI. Conclusion

As an advanced technical application, the ceramic combustion beam core liner for gas-coal mixed-fired double-beam lime kilns has brought significant efficiency improvements to the lime production industry. Its advantages in high-temperature resistance, corrosion resistance, improved combustion efficiency, and energy saving and consumption reduction help lime production enterprises improve product quality, reduce production costs, and enhance market competitiveness. With the continuous development and improvement of technology, the ceramic combustion beam core liner will be more widely used in the lime kiln field, promoting the entire industry to develop in an environmentally friendly and sustainable direction. 。

Previous article