项目介绍

本工程由河北携海工程技术有限公司进行总体规划设计、联动调试,系统主要包括:干粉料输送系统、加湿搅拌系统、供水系统、压缩空气硫化系统。本系统主设备采用双轴搅拌加湿机,每小时处理50t钢厂除尘灰,成品湿料水分可控制在8-10%。该系统通过PLC控制可实现全自动运行,无人值守。

项目概况

处理物料:除尘灰

处理能力:50吨/时

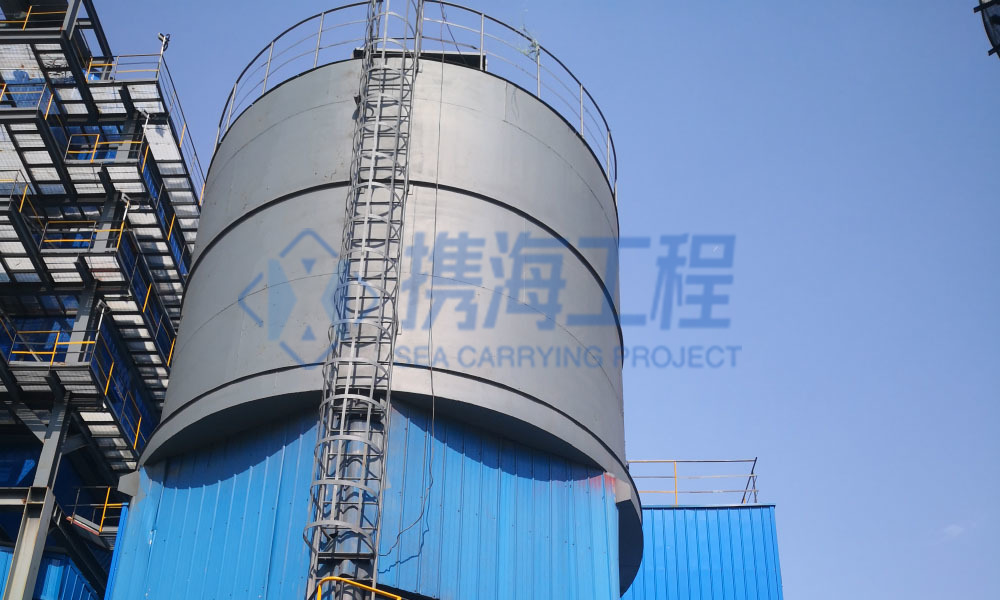

设备配置:9m长双轴搅拌加湿机1台、螺栓输送机2台、单机收尘器3台、250m³粉灰仓3套等主要设备。

解决方案

本项目为某钢铁厂环保排放创A达标工程,主要用于加湿搅拌高炉矿槽除尘灰;高炉炉前除尘灰;烧结机尾除尘灰;烧结、球团转运筛分除尘灰;高炉、烧结原料转运除尘灰;烧结、竖炉静电除尘灰;白灰生产、烧制、转运过程中的除尘灰;高炉重力除尘灰;高炉煤气干法除尘灰等。项目设计周期1个月,联动调试7天后各设备运行稳定,区域排放标准满足环保创A各项指标要求,为企业环保升级提供了一整套智能化解决方案。

现场图片

免费获取更多案例信息

如果您对我们的产品感兴趣,请留下您的电子邮件,我们将尽快与您联系,谢谢!