项目介绍

本项目由河北携海工程技术有限公司采用EPC总承包模式进行承建,生产线主体为3座20t/h立式烘干机,利用石灰窑烟气作为烘干热源同时热风炉补充部分热量,用于烘干碳材。烘干后碳材终水分不大于1%,且稳定合格率在95%以上,破碎率低于3%。大大降低了企业的原料成本。

项目概况

处理物料:兰炭

处理能力:60吨/时

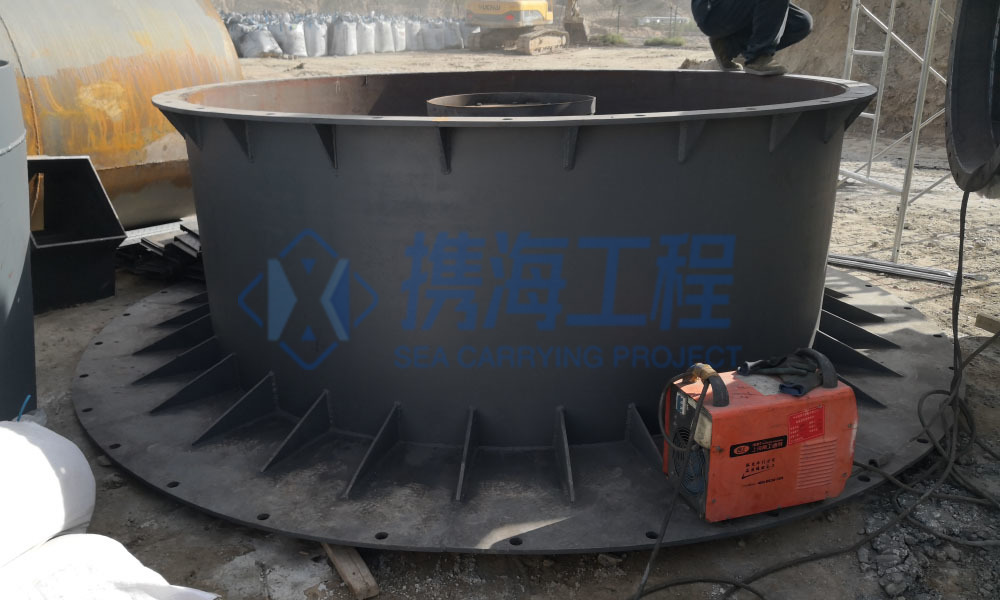

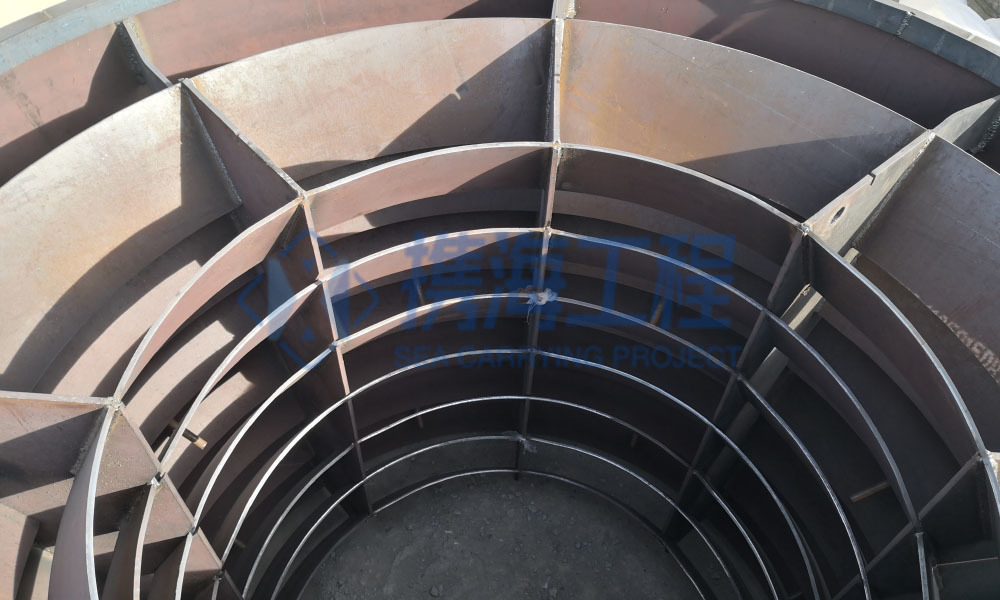

设备配置:20t/h立式碳材烘干机3座、热风炉2台、脉冲袋式除尘器3台等主要设备。

解决方案

在满足生产总规模要求的前提下,首先,项目采用成熟单机多台布置的原则,以达到生产线流畅、节约土地的目的;其次,项目采用智能化机器设备、自动化生产线、智能检测系统等,以提高生产效率和产品质量;项目中我司设计和制造高效节能的机械设备、可循环的环保型设备及环保净化控制系统;采用先进的节能技术和材料,降低能耗,减少环境污染,同时利用一些企业在生产过程中产生的废料、废气等,再利用后变废为宝,为企业创造了节能、高效、环保的碳材烘干生产线。

现场图片

免费获取更多案例信息

如果您对我们的产品感兴趣,请留下您的电子邮件,我们将尽快与您联系,谢谢!